Laminating

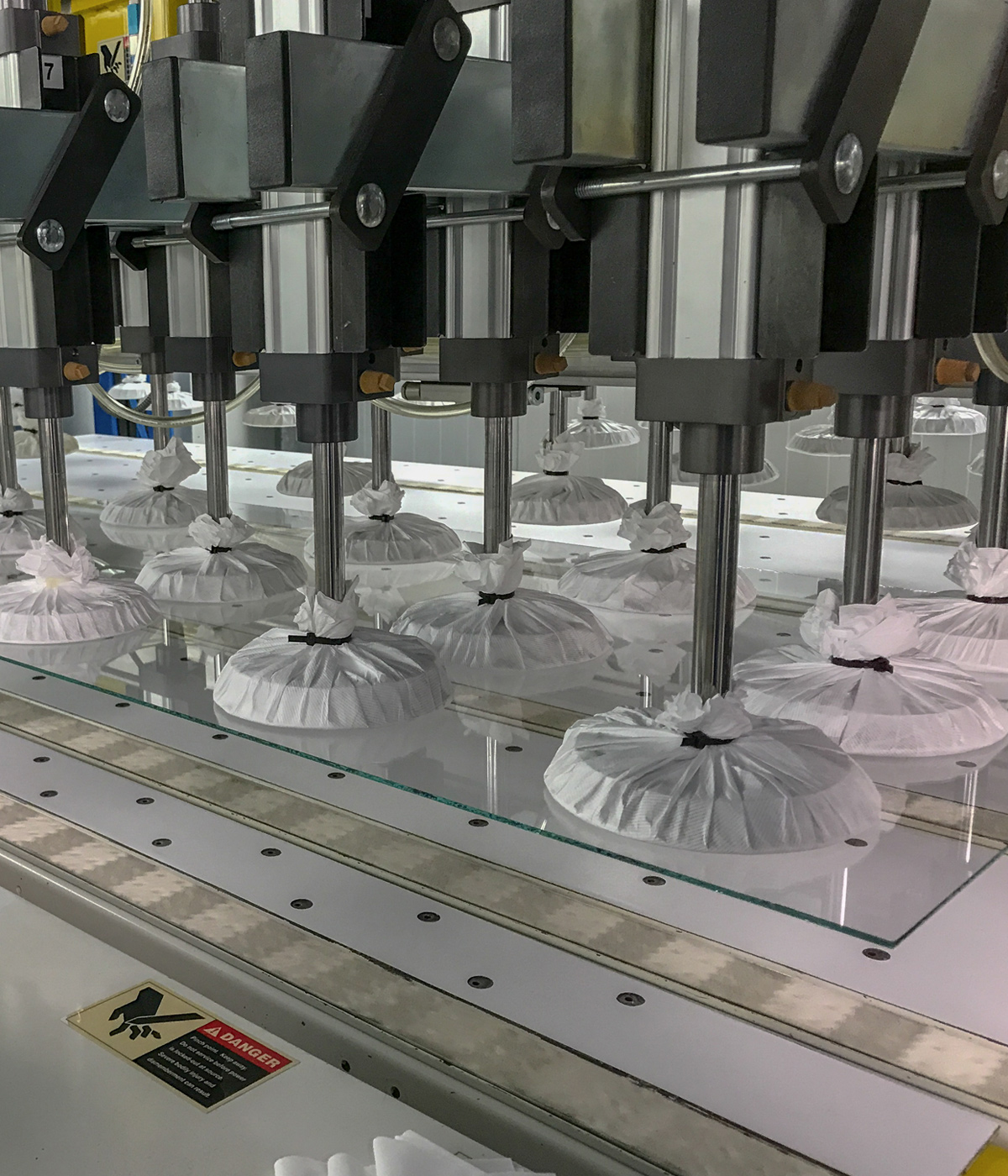

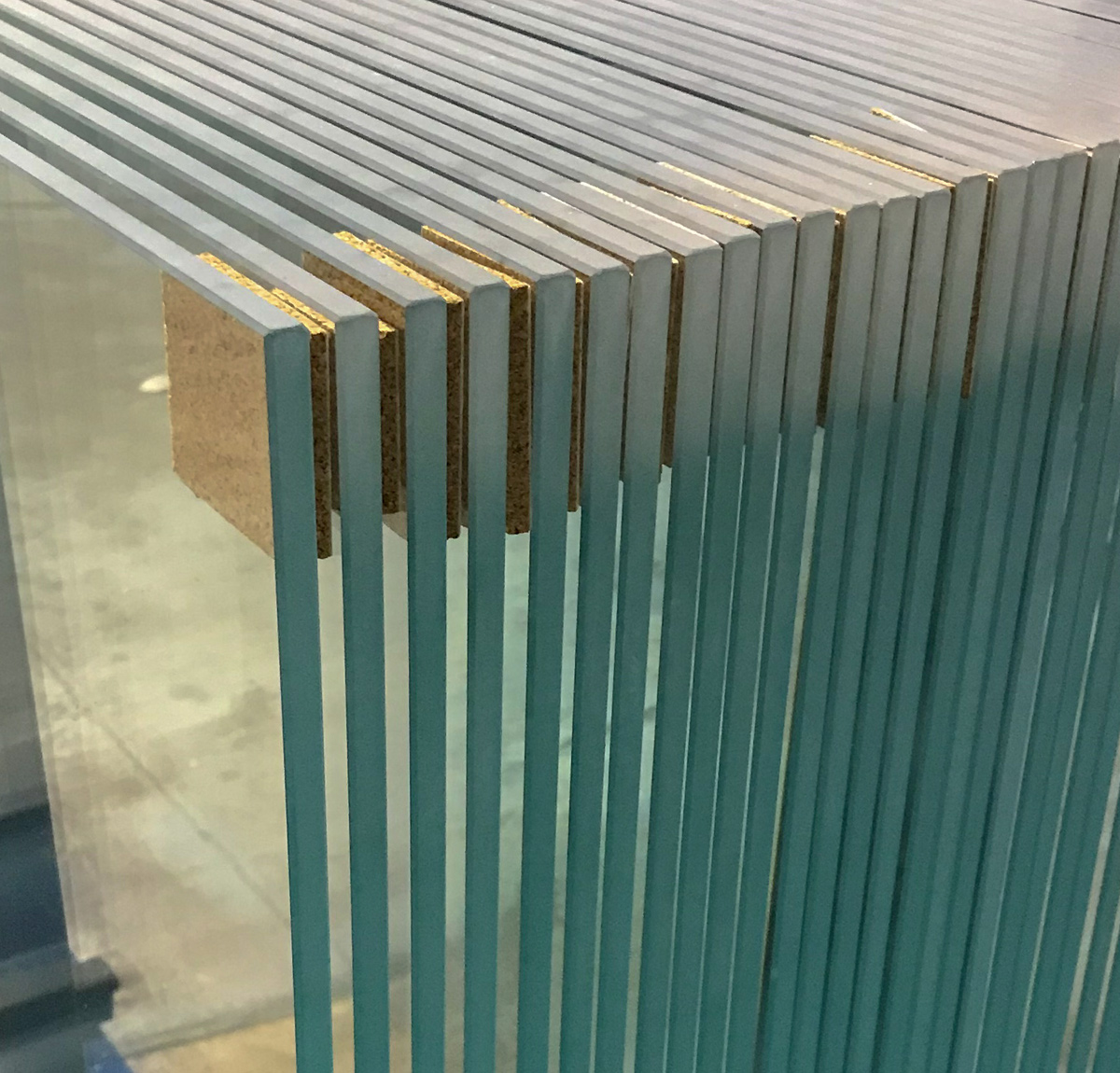

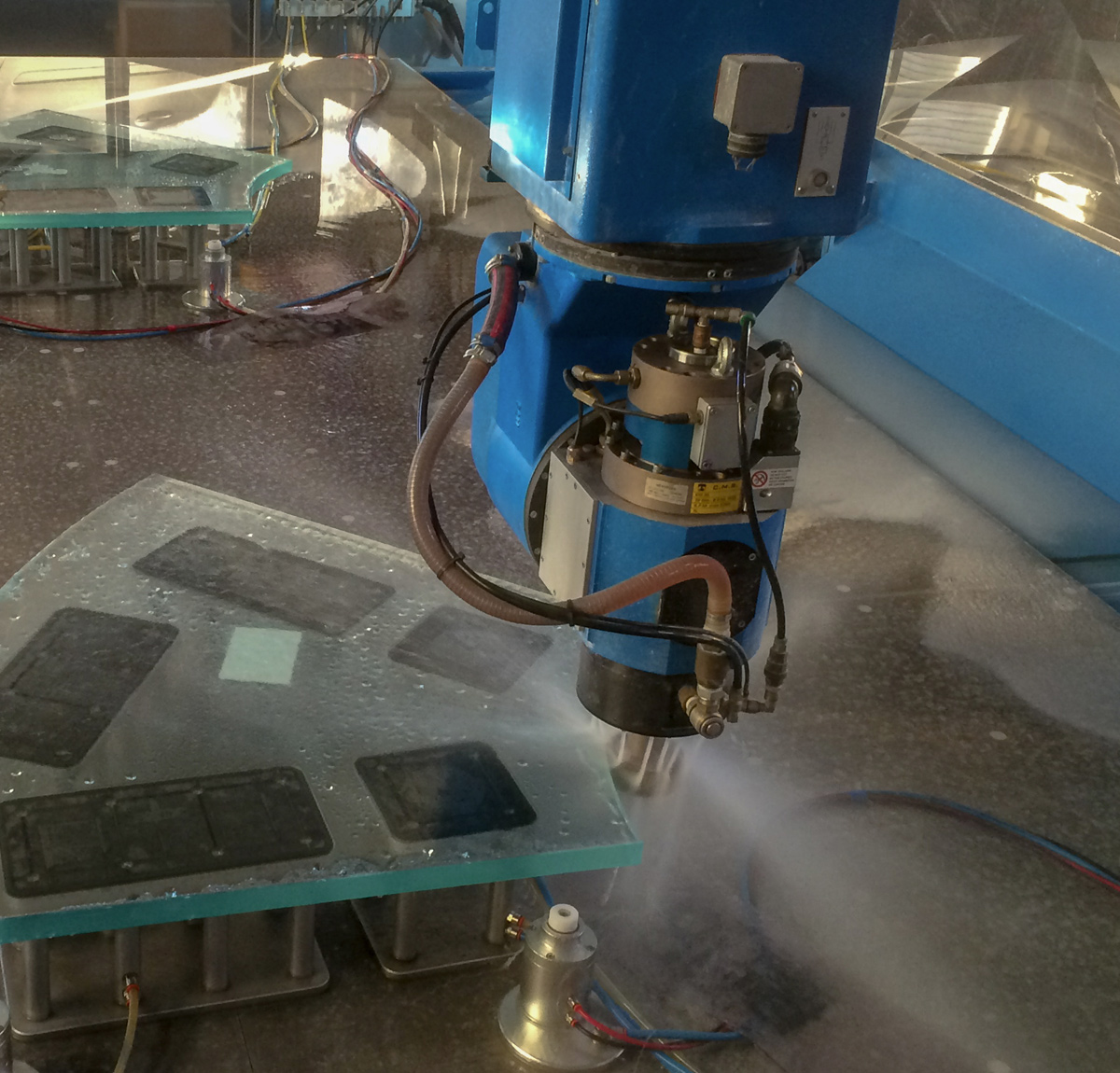

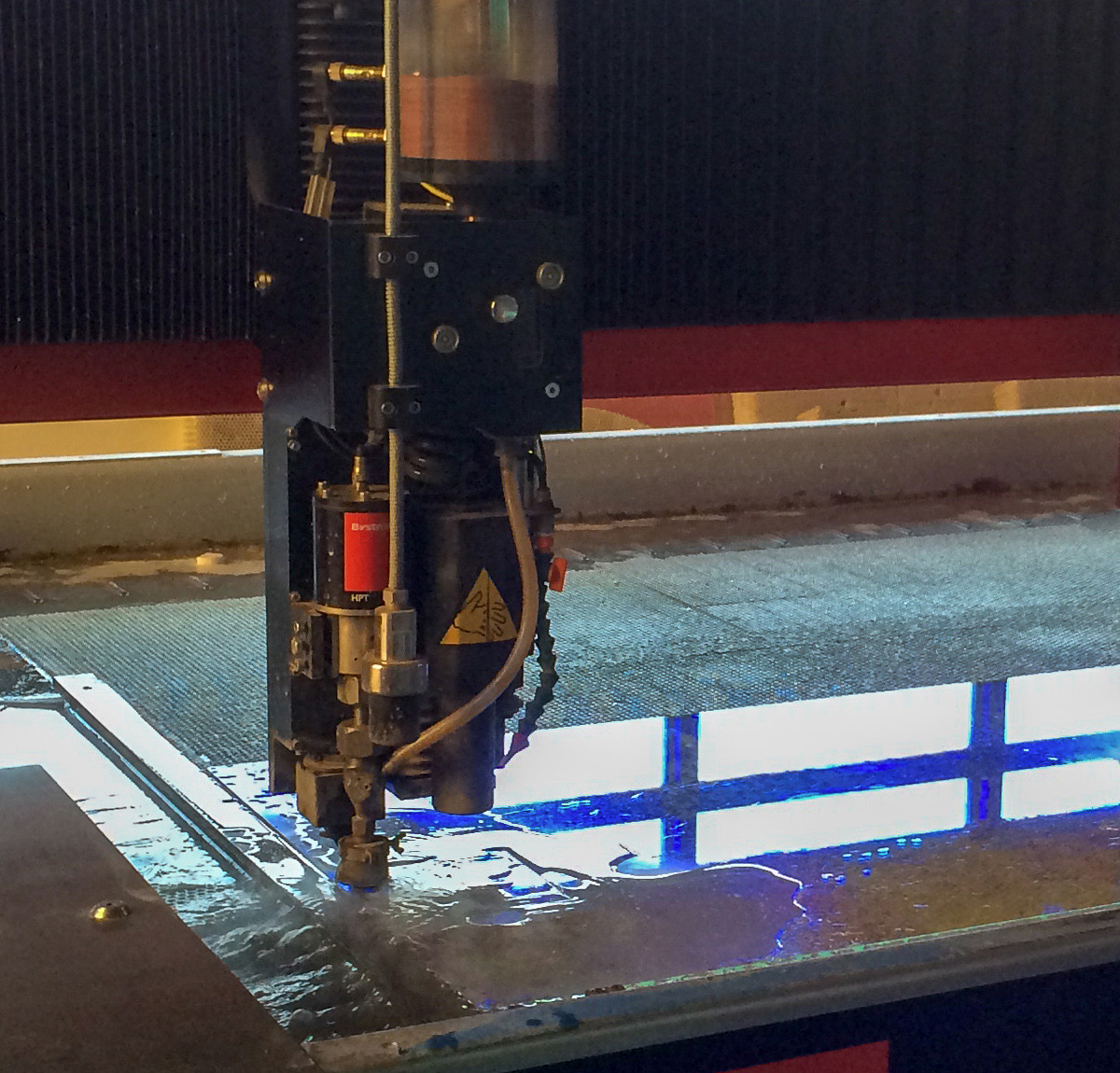

Glass enters the temperature and humidity controlled clean room after being sent through the horizontal washing machine. Inside the glass plates are automatically positioned and transferred to the layup station where the proper interlayers are placed onto the glass sheet according to the instructions delivered via a PC interface. After the interlayers are placed onto the glass the final glass sheet is placed on top and the excess interlayer is trimmed. The glass is then transferred through to the infrared ovens and press rolls or individually vacuum bagged for more complex assemblies.

The autoclave is the final step where the lamination takes place. The glass goes through a cure cycle of heat and pressure where it reaches its final bond.